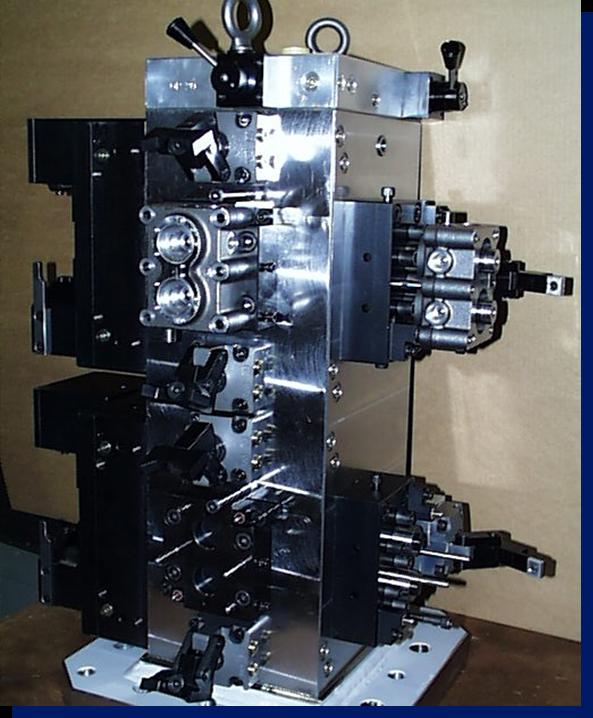

Our expertise and experience in CNC precision machining of medium to large complex parts with Robotic integration have led to numerous trade publication articles about our unique capabilities. With ten full-time engineers on our staff, knowledge of materials, machining, and machine tools, our capabilities go beyond our current customer base.

Mennie's engineering knowledge and experience can help you in the design and prototype phase to optimize your parts for manufacturability; from viewing customer's drawings with Auto-CAD to creating our own fixtures at our 30,000-square-foot tool room located one mile from our production facility. In addition, our engineering department utilizes the latest software for computer-integrated manufacturing.

Company History

- Founded in 1970 by Hubert J. Mennie and his wife, Cheryl.

- In the 1980s, MMC designed and produced CNC equipment along with low and medium-volume production machining.

- In 1990 MMC expanded into a 30,000 sq. ft. facility, transitioning to high-volume manufacturing with robotic closed-loop machining cells. New markets automotive and construction industries.

- In 2000 MMC expanded & Consolidated into a new 130,000 square ft. facility.

- In 2003 MMC completed yet another 85,000 sq. ft. expansion onto their new facility to facilitate future customer demands.

- In 2014 MMC was certified as “Women-Owned Small Business Status“

- In 2015 “SBA HUBZONE” Certified Business with Federal Government.